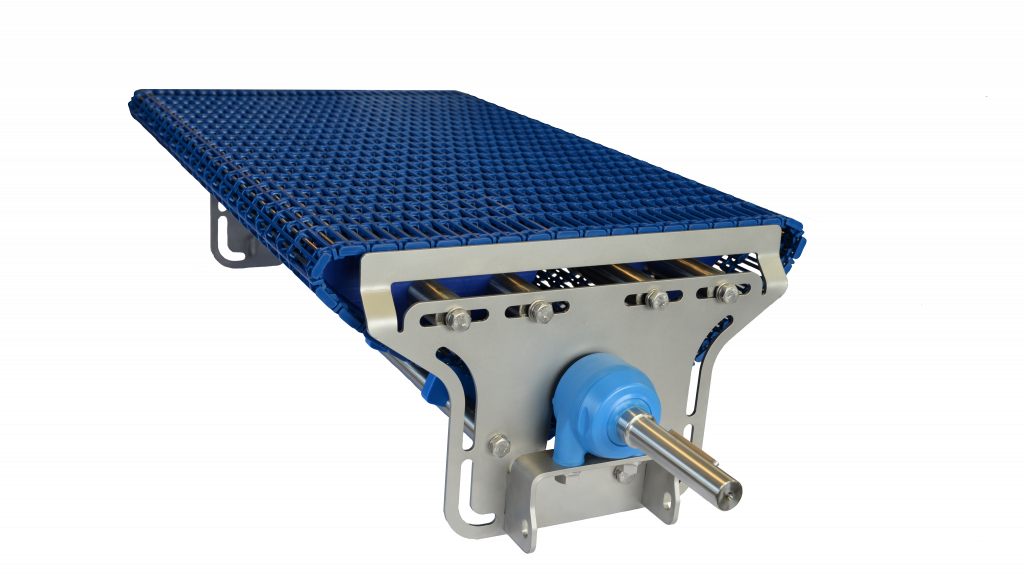

Jonge Poerink Conveyors has developed a new hygienic transfer conveyor. The completely new transfer conveyor has a robust belt that is easy to repair. The new conveyor belt has been designed following USDA and FDA guidelines, ensuring the highest hygienic standards. The open structure of the belt makes it possible to clean the belt and conveyor thoroughly. In addition, the centrally positioned drive offers optimal flexibility.

This new conveyor belt from Jonge Poerink Conveyors offers a compelling alternative to traditional mesh belts. It provides a solution to some of the challenges associated with mesh belts while maintaining the benefits that have made them popular in industrial environments. This innovation positively impacts industries that depend on efficient and hygienic material handling and conveying systems.

The Sani Transfer has knife edges on both sides. Together with the new belt design, this enables a smooth and tight transfer, improved tracking, and product stability while allowing a minimum gap between conveyors.

| Belt width (mm/inch) |

| 203 / 8″ |

| 305 / 12″ |

| 406 / 16″ |

| 508 / 20″ |

| 610 / 24″ |

| 711 / 28″ |

| 813 / 32″ |

| 914 / 36″ |

| 1016 / 40″ |

Are you ready for the future regarding the hygienic handling of your food products?

The key features and benefits of the newly designed conveyor belt:

Unlike existing wire mesh belts, the new conveyor belt is robust and easy to repair. This will lead to reduced downtime and maintenance costs.

The belt has been designed following USDA and FDA guidelines, ensuring high hygienic standards. This is crucial, especially in industries where cleanability and hygiene are requested.

The open structure of the belt allows for thorough cleaning, both through dry and wet washdown execution. This is essential to maintain product quality and prevent contamination.

Like wire mesh belts, the new belt offers a small contact surface. This minimizes the chances of product damage or deformation during transportation. Also, does the belt not ‘pinch’ the products.

The belt is resistant to high and low temperatures, ranging from -30°C to +80°C. This extensive range in temperature resistance makes it suitable for various environments and industries.

The centrally positioned drive provides optimal flexibility and allows the belt to run in both directions. This can be advantageous in applications where the direction of movement needs to be changed.

| Belt material | POM/Acetal Food-approved |

| Rod material | Stainless steel |

| Available belt width | 203, 406, 610, 813, 1016 mm |

| Support material | UHMW |

| Belt radius on in- and outfeed | 19 mm incl. belt |

| Product temperature range | -30°C to +80°C |

| Max. belt speed | 30 mtr./min. |

| Drive method | Sprockets (positive driven) |