The standard Puma is versatile and well-suited for general applications. At the same time, the Puma CR is built to handle more demanding conditions, making it ideal for industries dealing with abrasive materials and high-speed operations. It’s essential to select the right conveyor type based on the specific requirements of your industry and the materials you need to transport.

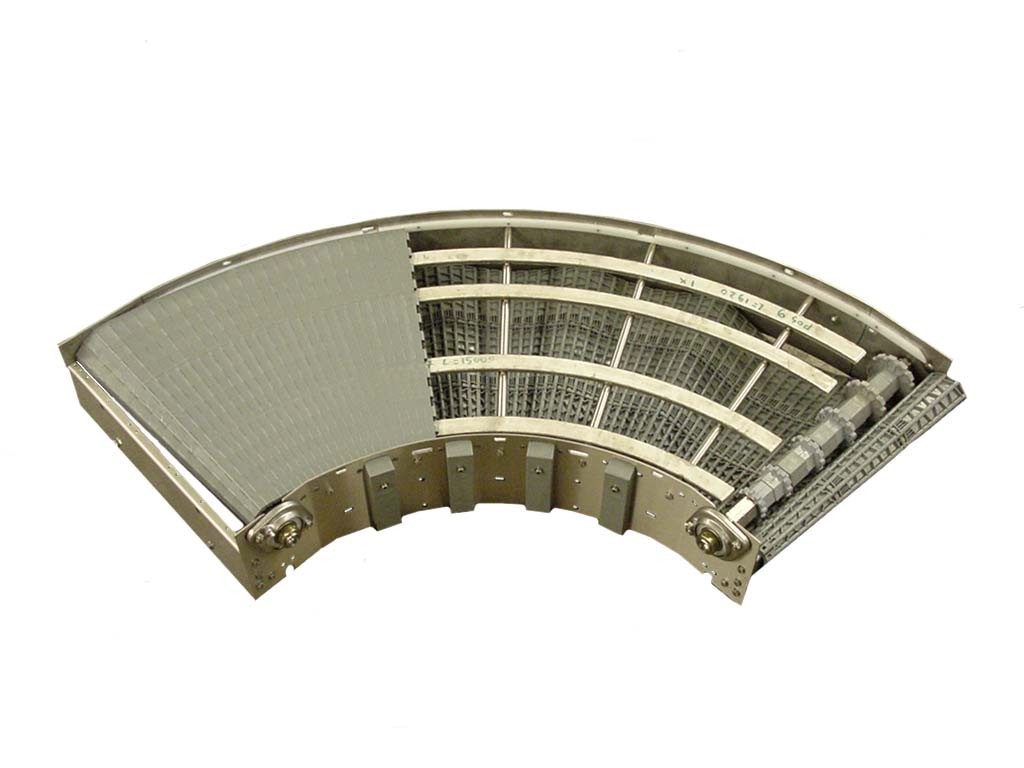

| Type | Curved conveyor with a plastic panel belt |

| Application | Suitable for various industries, including packaging and beverage |

| Belt Material | The conveyor uses a robust plastic panel belt |

| Key Features | Designed to connect with straight conveyors, allowing for a seamless flow of materials in a production or packaging line. The plastic panel belt is solid and has a proven track record for versatility, durability, and low maintenance requirements |

| Type | A more robust version of the Puma conveyor |

| Application | Recommended for high-speed operations, oversized loads, and the transportation of abrasive substances |

| Belt Material | The conveyor uses a robust plastic panel belt |

| Key Features | Features conical rollers (CR) for enhanced durability and performance, making it suitable for heavy-duty and abrasive material handling. They are specifically designed for transporting materials like sugar, salt, sand, fertilizer, and similar substances, which can be harsh on conveyor systems |

| Belt material | Panels: glass fiber reinforced Poly Amid (PA), Acetal (POM) Rods: Stainless Steel |

| Frame material | Mild steel or Stainless Steel |

| Frame finish | Stainless Steel K320 or RAL color painted (option) |

| Drive method | Sprockets (positive driven) |

| Available belt width | 200 to 1600 mm |

| Inside Radius | 600, 800, 1000, 1200, 1400, 1600mm |

| Max. increase | 1500mm/turn |

| Max. belt speed | 60 m/min on middle radius (R2) |

| Temperature range | -30°C to 100°C |

| Possibilities | Inclining/Declining |

| Available angle | min. 20deg |