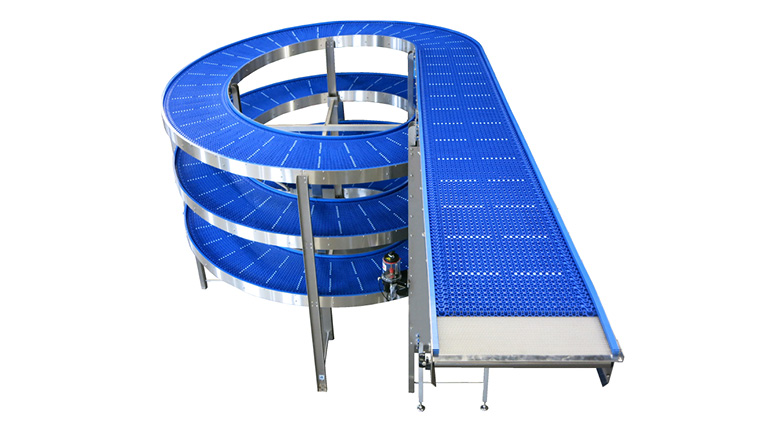

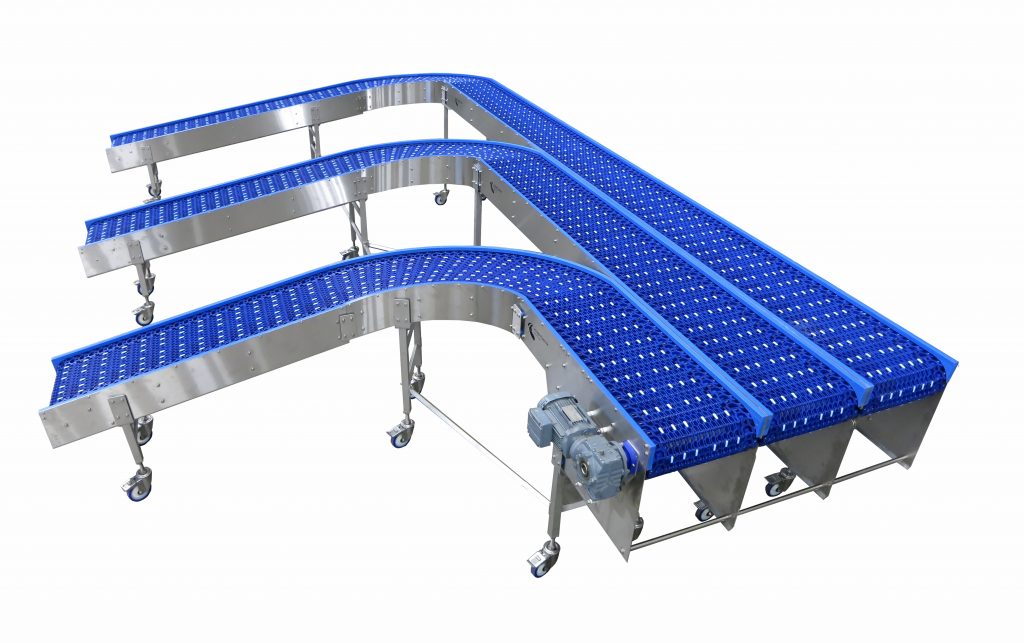

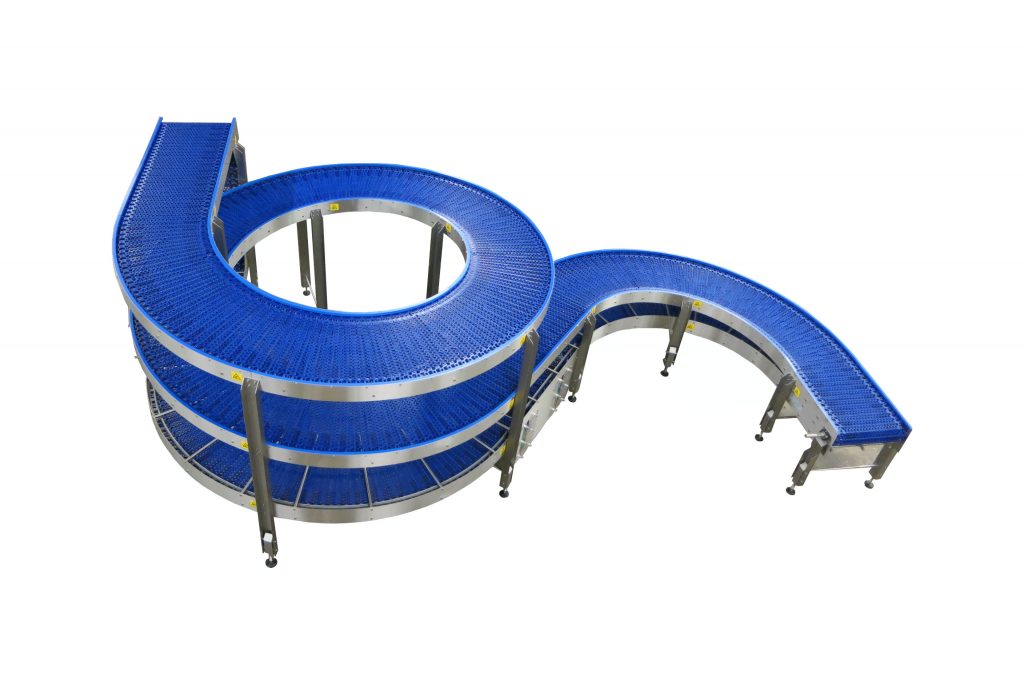

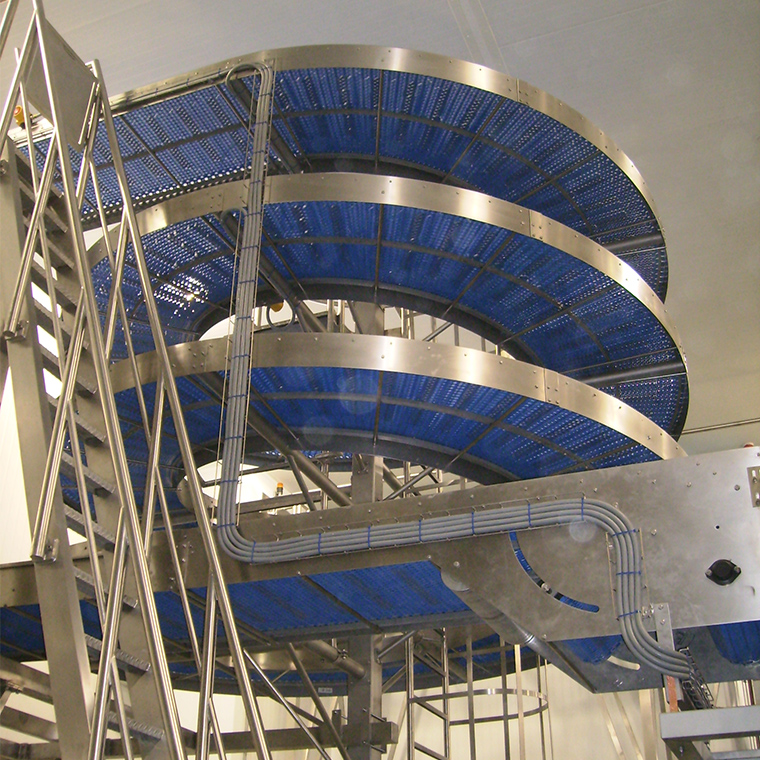

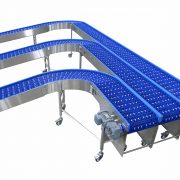

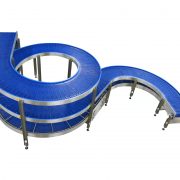

Do you want a minimal loss of space and transport your products efficiently and hygienically up or down? Then, the JPFD Spiral is the ideal Spiral Conveyor.

The belt: the Advantage 200 is a strong plastic belt with stainless steel open panels, so it is easy to clean. The belt includes friction inserts for solid and smooth up-and-down transportation of products such as frozen items. Our belts are one of the few in the world that are certified by NSF and USDA. The ultimate guarantee that you are buying the best quality.

The back of the belt consists of bearings, which ensures a very low friction coefficient. Because of that, lubrication is not required, and the belt is durable and hardwearing. The stainless steel frame is strong, and our engineers can design the JPFD Conveyor entirely to your needs. The straight in- and output provide the perfect connection. JPFD Spiral is specially designed for the food industry and is suitable for cooling and freezing applications. More information or questions about these “high-level Spiral Conveyors”

please contact Jonge Poerink Conveyors.

| Belt: | Acetal (POM) panels, Stainless-steel rods, PA6 (Nylon) anti-slide |

| Minimum belt width: | 254 mm (10”) |

| Belt pitch: | 50.8 mm (2.0”) |

| Belt thicknness: | 14.3 mm |

| Rod diameter: | 6 mm |

| Turn ratio IR/BW, IR = inside radius, BW = Belt width: | minimum 1.5 |

| Frame material: | Stainless steel |

| Turn direction: | Bi-directional |

| Drive method: | Sprockets (positive driven) |

| Standard Sprockets: | Teeth, pitch diameter (mm), 10 teeth, 164.3 mm, 13 teeth, 212.3mm |

| Temperature range: | -45°C to + 80°C |

| Belt speed up to: | 35 m / min |