JPHD Series has a modular design and a wide range of in/out-feed configurations. This makes the JPHD Spiral flexible, and the spiral can be customized to your needs, so it fits perfectly in your production environment. You can maximize the floor area with a radius of only 500 mm and an area of 1636 mm. The belt always remains in place by using robust stainless steel bearings on both sides of the belt and ensures quality and reliability.

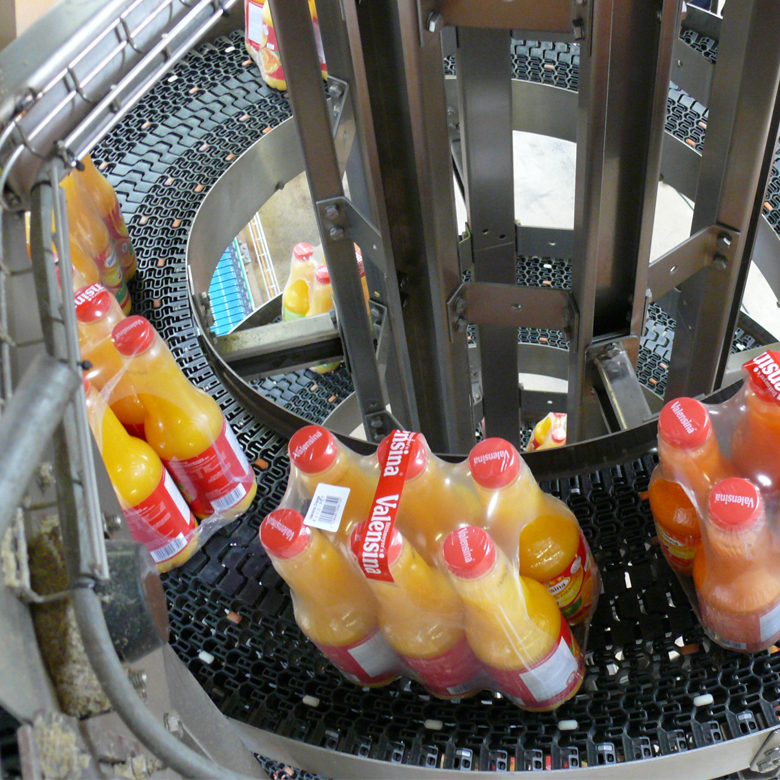

JPHD Spiral is designed for heavy-duty use: high-capacity transport of heavy product loads vertically and horizontally. You can configure the spiral precisely with a modular setup and various in/outfeed configurations. You can adapt the JPHD Spiral to the layout of your production area.

The rigid spiral construction and high-quality components and materials ensure a long lifetime and low maintenance costs. The JPHD Spiral has a strong belt with stainless steel rods and a stainless steel link chain, maximizing your plant’s uptime.

JPHD Spirals have a floorspace-saving design. With a small footprint and a slight curve radius of just 500 mm, you optimize your capacity. The compact spiral fits into almost any plant design.

JPHD Spirals up to 6 meters will be delivered in one piece. The spiral must only be upright, and the motor should be connected. JPHD Spiral is up and running in no time.

The JPHD Spiral is center-driven by a robust stainless steel chain link. The friction coefficient is reduced to a minimum using a guide bearing in the middle of the belt.

The plastic panels of the belt are fixed over the entire width of the belt with a 6 mm stainless steel rod. This design ensures a flat belt surface and prevents belt panels from breaking out. Guide bearings at both sides prevent the flipping of the belt. This belt design reduces the risk of unexpected breakage and makes the JPHD a reliable conveyor.

The JPHD belt panels are made of glass fiber-reinforced polyamide to prevent wear during heavy-duty use. The excellent wear resistance is perfect for transporting packed bottles and cases—friction top for conveying slick products. JPHD Spirals have a friction top conveyor belt to elevate smooth products like plastic or frozen items. The anti-slide is made of Desmopan. This strong material with a soft touch is durable and long-lasting.

JPHD Spirals need only one drive. The drive has a robust stainless steel link chain connected to the belt.

| Belt | PA6 Glass fiber reinforced, polyamide, stainless steel rods and links, Desmopan anti-slide (option) |

| Belt width | 308 mm (12”) |

| Belt pitch | 27.4 mm (1.08”) |

| Belt thickness | 19 mm |

| Rod diameter | 6 mm stainless steel |

| Inside belt radius | 500 mm |

| Outside belt radius | 808 mm |

| Guide bearing middle | Stainless steel 627-2RS (Ø 22) |

| Guide bearing outside | Stainless steel 627-2RS (Ø 22) |

| Frame material | Stainless steel or painted steel |

| Sprocket | Z = 14, Acetal (POM), Stc = 123, 13 mm |

| Max. belt speed | 35 m/min |

| Temperature range | 0 - +60°C |

| Drive method | Sprockets (positive driven) |